Case Highlight

Cold Chain, New Energe, Pharmaceutical, etc.

Utility ration of locations

Quick launch

ROI

Cold Chain –100% humidity, 0°C-5°C

Pain points

• In urgent need.

• Extremely humid environment requires the storage solution’s stability.

• Low temperature working environment cause hiring difficulty.

Spotlights:

• 4 months landed.

• Lonlink's fresh keeping solution: stable and flexible.

• Unmanned intelligent intensive storage solution.

视频播放失败,请联系站点管理员!

Pharmaceutical: -25°C frozen

Pain points

• Tight crowed space.

• Decentralized warehousing and production processes reduced efficiency.

• Difficult to recruit workers in a -25°C environment.

Spotlights:

• Cold chain customized shutters.

• Customized vertical conveyors.

• Link warehousing and production lines to enhance efficiency.

• Unmanned intelligent intensive storage solution.

New Energy: flexible scheduling

Pain points

• Multiple SKUs are hard to manage for workers.

• Decentralized production processes reduced efficiency.

Spotlights:

• 24 shuttles

• 17 conveyors

• Flexible & stable software scheduling.

• SKUs mixed storage.

• Link all manufacture processes to enhance efficiency.

视频播放失败,请联系站点管理员!

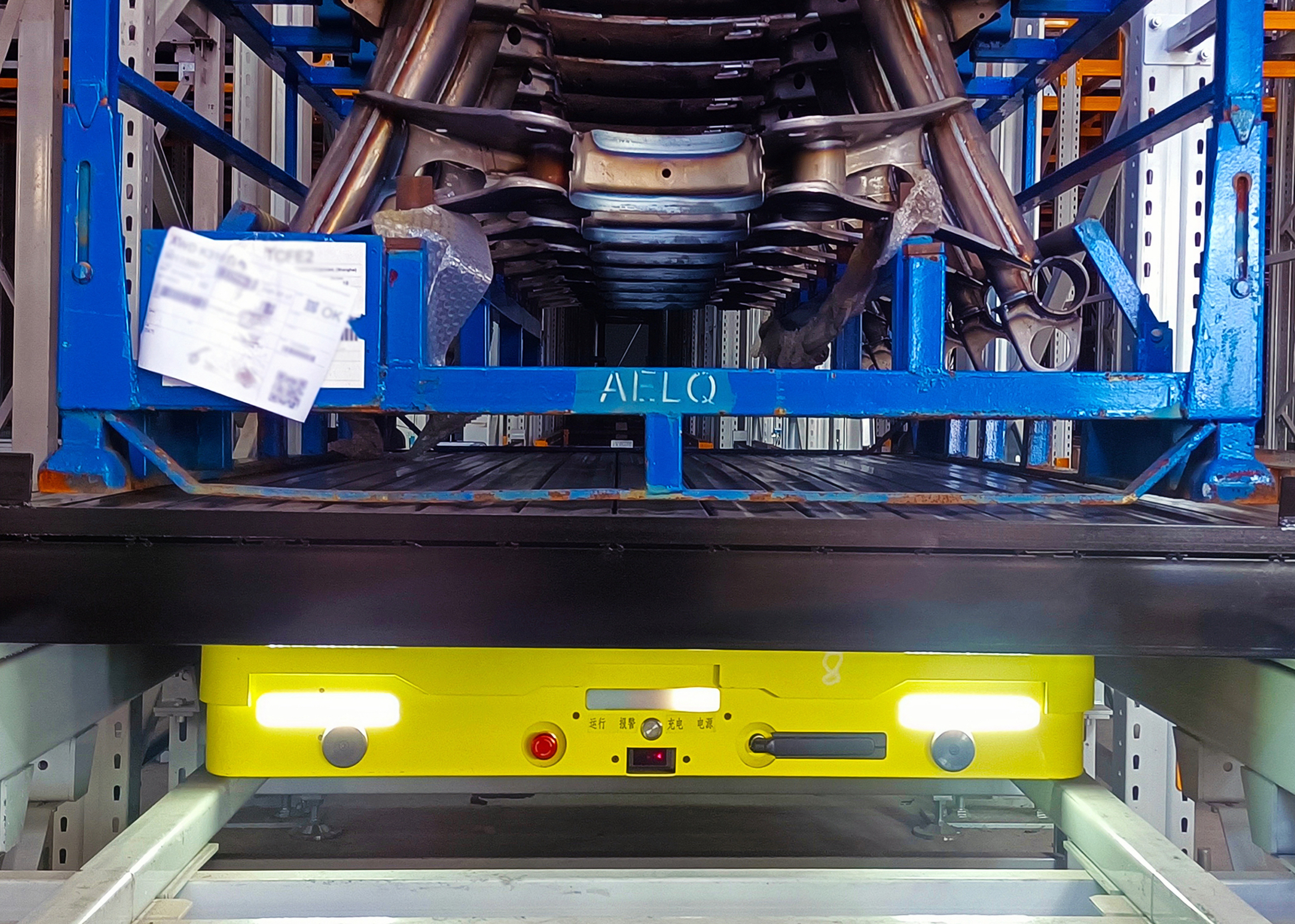

Automotive: heavy load

Pain points

• Heavy load: 1500kg.

• Nonstandard pallet size: 1.5m * 2.5m.

• Storage area of production lines: high output.

• Heavy workload and duty cause high labor cost.

Spotlights:

• Heavy-loaded shuttles: up to 2 ton.

• Lonlink’s shuttles can support most of the nonstandard pallets.

• Flexible software scheduling.

• Efficiency in and out of storage: 200 pallet/ hour.

E-commerce:shared warehouse & shared cost

Pain points

• Need to storage and manage at least 500 companies’ goods.

• The total needs of storage is uncertain.

• Strict fire regulations.

Spotlights:

• Lonlink’s solution up to 24 meters high, use every inch of the possible storage space.

• Flexible software scheduling: support 500+ companies shared the intelligent warehouse.

• Phased planning, no need to invest in future uncertainty.

• The fire sprinkler and pipe system on each floor supported by the rack layout.

视频播放失败,请联系站点管理员!

Manufacturing: 10000+ SKUs on the 4th floor

Pain points

• More than 10000 SKUs are hard to manage.

• The warehouse is on 4th floor, normal intelligent storage solutions can only install on the 1st floor.

• The warehouse’s in-and-out needs are highly frequent, workers’ workload is heavy.

Spotlights:

• Multiple SKUs store on one pallet.

• Good-to-Person: picking the chosen one from the pallet then re-store the rest.

• Lonlink’s intelligent pallet intensive storage system can install on every floor.

• The efficiency of unmanned storage in-and-out: 110 pallet/ hour.

视频播放失败,请联系站点管理员!